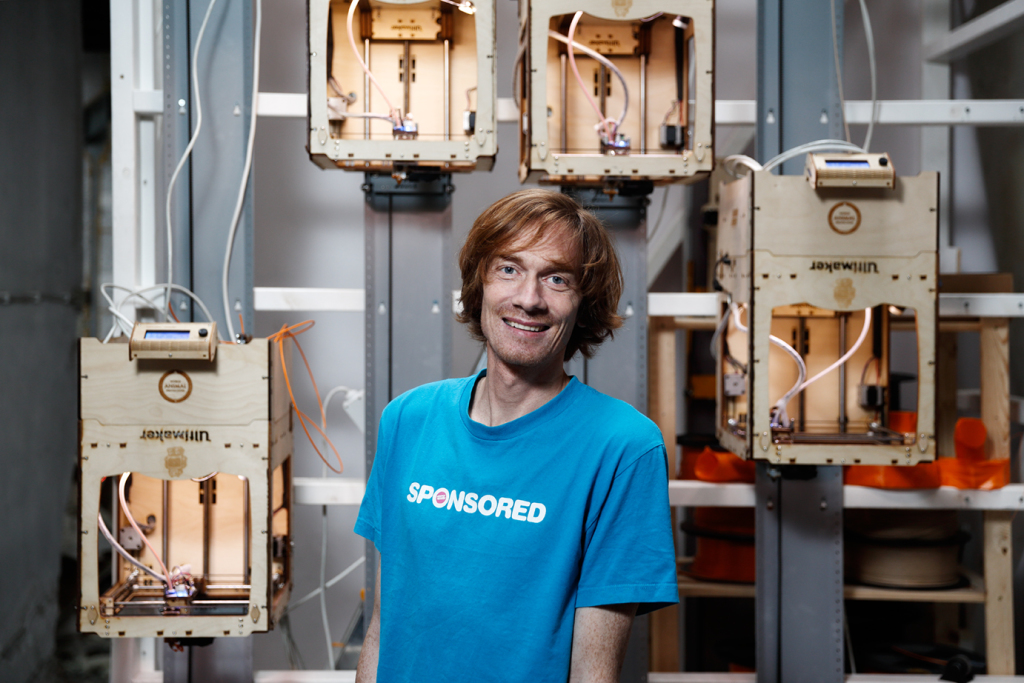

Joris van Tubergen (1977) is a designer, inventor, and expert in the field of digital fabrication and 3D printing. His knowledge and techniques are used in several projects and installations renowned by leading (international) galleries and museums. With his straightforward way of explaining his vision of 3D printing and the future role of digital fabrication in society, he is frequently asked to speak at international and national broadcasts on television, interviews and public lectures. He teaches digital fabrication at several educational institutions a.o. TU Delft, KABK, HKU, ArtEZ, and WDKA.

Joris studied Industrial Design Engineering at the Delft University of Technology in the Netherlands. His very early fascination for digital production resulted in 2008 in joining Fablab Protospace in Utrecht. Until now, he still is the Creative Director at Protospace. Since the start of the Fablab, he has supported the RepRap development – an open-source 3D printer that you can build yourself. In 2010, the popular RepRap masterclasses at Protospace resulted in the development of Ultimaker: The world-leading desktop 3D printer firm today.

As an Independent 3D print expert, he is involved in innovative Dutch startups like Ultimaker, 3D Hubs, Aectual and Fairphone. When 3D hubs was featured in the Dutch national 8 o’clock news Joris was their first hub. From the beginning, he is advising Aectual on the engineering of their large scale (robotic) 3D printers and helping them with material experiments and print strategies.

Because Joris was one of the first to think about building the printer AND what to do with it, he has been an influential factor and driving force in developing the (Dutch) 3D print industry for more than ten years. His open designs have been used at all fairs in recent years to show what the printer in question can do. But his close connection with Ultimaker and Aectual also ensures that his ideas become feasible from the R&D department there. With the right questions and knowledge of possibilities, the design-driven adjustments in firmware, software, and hardware ensured an even better printer and vise versa.